Woodgrain Cladding vs Real Timber: What’s the Difference?

Choosing between woodgrain cladding vs real timber isn’t just a design decision; it shapes how a space looks, lasts, and holds up over time.

Whether you're planning a garden wall or reviewing timber cladding alternatives for an out building project, the real differences aren’t always obvious. With questions around cost, upkeep, and sustainability, it helps to look past first impressions.

This article breaks down the real timber cladding comparison to help you decide what fits your plans best.

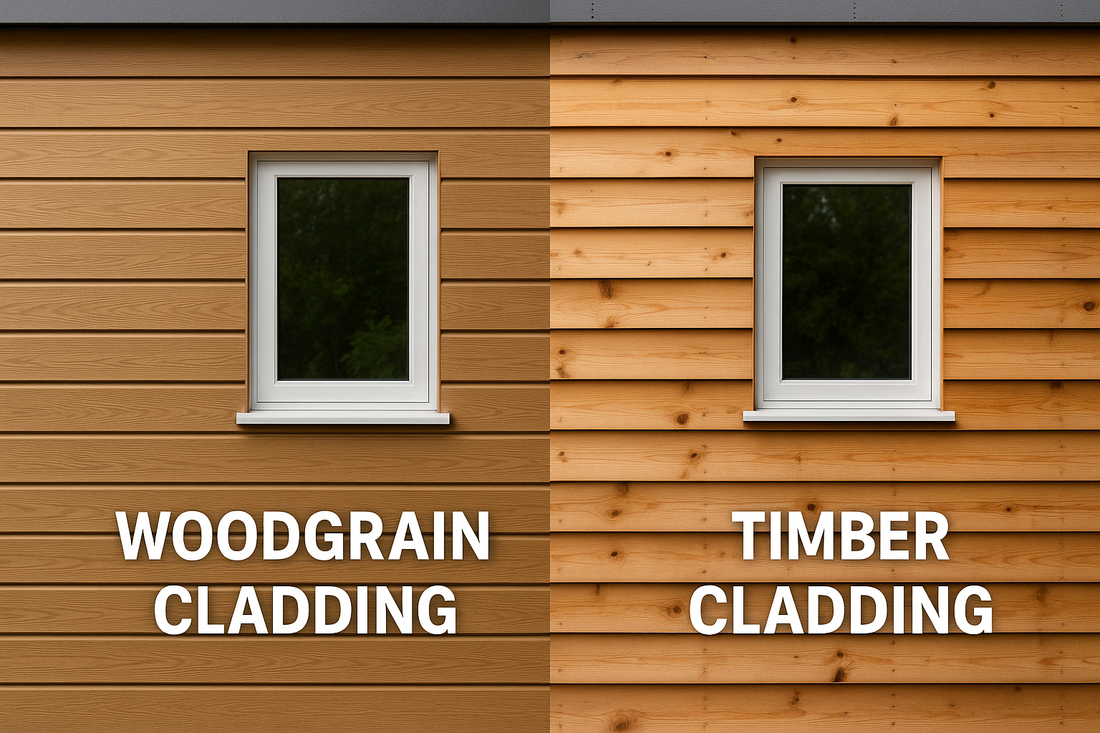

Appearance

In a side-by-side outdoor cladding comparison, the finish is often where opinions form fast. Woodgrain cladding offers a controlled, repeatable grain that mimics timber without the knots, cracks or colour variation. It’s tidy, consistent, and made to match.

Real timber cladding, meanwhile, has more character, variations in tone, grain, and small imperfections. It’s unique, but harder to control visually across large areas.

If you're after natural looks without surprises, woodgrain cladding delivers a realistic finish that's stable and less prone to sun fade.

Material Composition and Manufacturing

What goes into each board affects how it behaves. Composite woodgrain panels are made from recycled plastic and reclaimed wood fibres, pressed together with binding agents. The result? A dense, uniform board that’s built to last and finished with a timber-like surface.

Real timber cladding is cut from solid wood, softwood or hardwood, then dried, milled and sometimes treated. Its look and longevity vary by species and care.

The big difference is consistency. Timber has more variation and natural charm, but composite tends to deliver a predictable, stable finish, something many installers and renovators appreciate when planning layouts or scaling a project.

Durability and Resistance to Weather

How cladding handles the elements is where differences start to show. Here’s a quick look at how composite cladding vs timber stacks up in practice:

-

Rot

-

Timber: Prone to rot without regular sealing, especially in damp conditions.

-

Composite: Doesn’t absorb water, so rot is rarely an issue.

-

Warping and Cracking

-

Timber: Can twist or crack over time, especially if exposed to extreme temperatures or inconsistent airflow.

-

Composite: Much more stable thanks to its engineered core.

-

UV Damage

-

Timber: Fades and greys if untreated, often within the first year.

-

Composite: UV stabilisers reduce colour fade, keeping the finish consistent.

-

Pests

-

Timber: May attract insects like termites or woodworm, depending on species and treatment.

-

Composite: Inedible to pests, making it a low-risk choice.

This part of the outdoor cladding comparison tends to tip in favour of composite for sheer resilience.

Maintenance Requirements Over Time

Whether you're managing a full garden makeover or just replacing a few panels, upkeep can make or break a material choice. Here's how low-maintenance cladding options like composite compare with real timber year by year.

|

Task |

Real Timber |

Composite Woodgrain Panels |

|

Annual Cleaning |

Soft brush + detergent wash |

Light wash with water, occasional brushing |

|

Recoating or Staining |

Needed every 1–2 years |

Not required |

|

Rot or Mould Treatment |

Spot treatments likely |

Unlikely, thanks to water resistance |

|

Splitting or Repair |

Boards may need replacement or sanding |

Minimal, usually stays intact |

|

Estimated Annual Cost |

£50–£100 (materials and time) |

£10–£20 (if anything at all) |

That’s the thing: timber often needs more than a little love to stay sharp, while composite tends to just get on with it. So if weekends are better spent enjoying the space rather than oiling it, composite wins on ease.

Environmental Impact and Sustainability

If you're weighing up timber cladding alternatives with the environment in mind, there’s more than one angle to consider. Real timber, especially when FSC-certified, is sourced from responsibly managed forests. That’s a positive, but only if harvesting and shipping are kept in check, and the timber’s lifespan justifies the impact.

Composite woodgrain panels, by contrast, are typically made using recycled plastic and reclaimed wood fibres. So, they reuse materials that would otherwise go to waste. The trade-off? They’re harder to recycle again at end-of-life, but they often last much longer before that even becomes a question.

In terms of ongoing impact, composite cladding tends to need fewer chemicals, coatings or replacement boards, another tick in the sustainability column. So while neither choice is perfect, composite may offer more long-term value for eco-conscious buyers who want a greener build without the garden work.

Cost Comparison and Long-Term Value

Initial prices can be misleading. On paper, real timber cladding often costs less per board than composite. But that’s just the starting point.

Timber requires treatment, staining, and more hands-on maintenance, all of which add up year after year. Boards may need replacing due to warping or rot, and even the best-kept timber tends to fade over time, prompting re-oiling or re-coating.

Composite cladding vs timber starts to look very different over 10–15 years. Composite panels hold their shape, keep their colour, and rarely need more than a wash. That’s where the savings stack up, not just in money, but in weekends you get back.

In short, you're not just buying boards, you're buying fewer chores later.

Quick comparison:

-

Upfront cost: Timber is slightly cheaper

-

Maintenance costs: Composite far lower

-

Time investment: Timber is much higher

-

Replacement risk: More likely with timber

-

Long-term savings: Favour composite

Installation Process and Flexibility

How easy the boards are to fit can make or break a project, especially for DIYers or smaller trade teams.

Real timber cladding can be heavy and often requires pre-drilling, sealing ends, and using visible fixings. It also reacts to humidity, so boards need spacing and adjustment on-site to prevent warping. Tools? You’ll need a decent saw, plus some patience.

Composite woodgrain panels, on the other hand, are typically lighter, uniform in size, and cut easily with standard tools. Many use hidden fixing systems, which not only speed things up but also leave a cleaner finish with no nails or screws on show.

So, if ease and speed are part of the brief, whether you’re on a job site or doing it solo, composite tends to feel more user-friendly right out of the box.

Lifespan and Warranty Differences

Cladding isn’t something you want to replace every few years, and this is where differences really add up. Real timber cladding can last 10–25 years, depending on the species and how well it’s looked after. But that’s the catch, it only holds up if you stay on top of maintenance.

With composite cladding vs timber, warranties tell their own story. Most quality composite boards come with guarantees stretching 15–25 years, often covering fade, stain, and structural integrity. That’s not just marketing; it reflects how these boards are built to behave.

If long-term peace of mind matters, composite gives you that bit more breathing room.

For those drawn to the feel of wood but wanting fewer surprises, composite woodgrain panels might be the smoother path, especially if you’re aiming for long-term savings or simpler installation. Still not sure? Contact us and we’ll help talk through the details.